Motor Test System (Internal PC)

|

- Model : KT-MTS-1200

- Motor test system (Internal PC)

- This motor test system tests induction type assembly motors(0.5 ~ 4 HP) widely used in all kind of applience as water pump, air compressor, vacuum cleaner, etc.

It tests stator coil resistance, surge, insulation of each 3 phase windings, and in case of single phased motor, each of the test items of main, sub coils.

And the tested results are displayed on the screen of the computer. When after those tests, it checks the idling current, idling power consumption and judges the product to be good or bad in 7 ~ 8 sec.

- Characteristic of Motor test system

(Model : KT-MTS-1200)

- Test object

- Surge test : 3 times (Between main, sub coil from each phase to phase or single phase)

- Resistance test : 3 times (Main, sub coil from each phase to phase and single phase)

- Hipot(puncture) test : 1 time (Between coil and core)

- Insulation Test : 1 time (Between coil and core)

- Idling current (high / low preset)

- Idling electric power (high / low preset)

- Test item : single phase 220 V, 3 - phase 380 V,

induction motor of grade a 0.5 ~ 4

HP

- Test time : Approx. 7 ~ 8 s

(Excepted loading and unloading

time)

- Price : (Included Jig)

|

Armature Test System of motor for a vacuum cleaner

|

- Armature Test System of motor for a vacuum cleaner

- This photo shows the armature tester.

The different point of this tester is that it's not an assembly tester, but it tests each test point of manufacturing procedure, so when after the

procedure is finished, the test of the product shall be finished at the same time.

- Test object : From the left panel of left cabinet.

- Surge Test : 3 times

- Resistance Test : 2 times

- Hipot Test : 1 time

- Judgement method : Good / Bad auto judgement,

display of Bad item

- Power supply : AC 220 V, 50 ~ 60 ㎐

- Price : (Included Jig)

|

Stator Test System of motor for washing machine

|

- Stator Test System of motor for washing machine

- Model : KT-1500 STS

- This is the test system for a special motor used in a drum type washing machine.

Recently the BLDC (Brushless DC) motorwhich can directly drive the drum is used in the washing machine to reduce the noise and to increase the efficiency of the consumption power.

According to this method, the rotation and the speed of the drum can be controlled perfectly.

- Test object

- Surge Test

- Resistance Test

- Hipot Test

- Phase test (Rotating direction, RPM, Phase angle)

- Price : (Included Jig)

|

Stator Test System of motor for washing machine

|

- Stator Test System of motor for washing machine

- Model : KT-1500 MTS (Stator Test System of BLDC Motor)

- This test system checks the performance of the

stator of BLDC motor which is used in drum type washing machine.

It has the torque meter which can measure the effeciency related to the output power(torque, RPM) for the input source power(V.A).

This kind of test is one of the most important item to verify the BLDC motor.

- Price : (Included Jig)

|

Stator Test System of motor for refrigerator

|

- Stator Test System of motor for refrigerator

- This test system checks the stator in an AC 220 V induction motor which is widely used in airconditioner's compressor.

It tests the surge & resistance of the winding coils, and hipot test, rotation of the rotor, and judges the product to be good or bad.

It has 2 test jigs(A, B line) to shorten the test time.

- Test object

- Surge Test : 2 ~ 3 times (Main Coil, Sub Coil,

Main Coil + Sub Coil)

- Resistance Test : 2 ~ 3 times (Main Coil, Sub

Coil, Main Coil+Sub Coil)

- Hipot Test : 1 time (Between coil and core)

- Rotation Test

: There's a dummy rotor inside of the stator

which is set on the jig table, and the dummy

rotor detects the rotating direction.

- Characteristic

- This Test System has two lines (A, B line) for test time short.

(Test time - approx. 4 s(Each A, B Line - 8 s), Excepted loading and unloading time)

- It is suitable to test mass-production due to the solidity formation and direct comparing method which reduces the effect from environments.

- Price : (Included Jig)

|

Stator Test System of motor for an air conditioner

|

- Stator Test System of motor for an air conditioner

- Dual Test Line, Stator test for single phase induction motor (220 V, 380 V)

- This test system checks the stator before it is assembled in a single phased induction motor used in AC 220 V, or 380 V. To reduce the test time, it has 2 test lines(A, B line), and when the stator is set on the jig table, the dummy rotor comes inside of the stator and checks the rotating direction.

And the voltage of the applied AC test power can be changed easily, it makes the system widely use of different models of products.

- Test object

- Surge test : 2 ~ 3 times (Main Coil, Sub Coil, Main Coil + Sub Coil)

- Resistance Test : 2 ~ 3 times (Main Coil, Sub Coil, Main Coil + Sub Coil)

- Hipot Test : 1 time (Between coil and core)

- Rotation test

: The method of using a dummy rotor in a test

jig.

- Price : (Included Jig)

|

BLDC Motor Test System

|

|

- BLDC Motor Test System

- The photo shows an example of BLDC motor system which tests a ventilator in a boiler used in home appliance.

This test system stands for the test of mass-production in assembled motor manufacturer.

It tests input current, RPM, and the speed that is related to the input voltage, and judges the product to be good or bad.

- Test object

- Input current

- RPM

- Rotating direction

- Test time : approx. 4 ~ 8 s (Timer for test time setting)

- Price : (Included Jig)

|

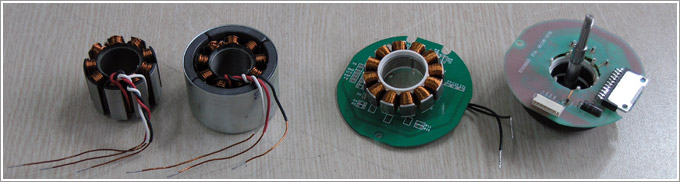

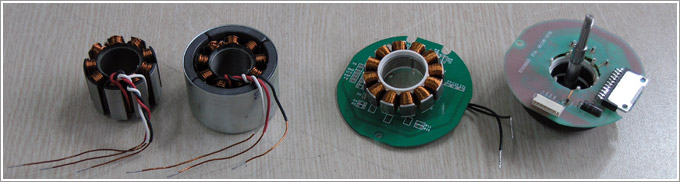

From the left, Stator Coil of 12V LPI(Liquid Propan Injection) BLDC Motor for LPG motor car, Outer Rotor shape of BLCD Motor, Stator of AC 220 V(DC 310 V) BLDC Motor used house's boiler fan, and the last picture is shape of attached Rotor and Drive IC of BLDC Motor

Explanation about BLDC Motor

BLDC(Brushless DC) Motor is more complicate and difficult structure and Driving method than general motor. Nevertheless, BLCD Motor used a lot of recently.

The reason why,

- Easy the speed control

- More efficiency

- More smaller

- Lessen the noise

- More used to farther

So BLDC Motor is increase in quantity be used in sporting goods, fan motor, precision instrument, car.

BLDC Motor is divide outer rotor type and inner rotor type like general motor according structure. And in case of BLDC motor, there are 2 type of drive method,

1. Hall sensor catchs the angle of spin and controls the drive pulse(larger type)

2. Sensorless drive type(smaller type).

However, in any type, the balance between the drive current to the rotor's angle is mismatched, or the drive pulse is cut in sudden may distroys the product while testing.

Besides, the drive IC or devices inside can be injured while surge test. It means the test for BLDC motor is very difficult.

Transformer Test System

|

- Transformer Test System

- To thoroughly test all kinds of Trans, the following items have to be tested (refer to figure).

- Idling current test

: Test how much input current flows on the

condition of impressed regular working voltage to

the primary part (P)

- Hipot(puncture) test

: As below Figure, in case that a second part(S)

output is four, the places of Hipot(puncture) test

are between P and core, P and S1∼S4, Core and

S1∼S4, S1∼S4, That is, Hipot(puncture) test is

performed between 4 coils mutually. Therefore

the no. of total step which needs Puncture test is

4 times.

- Surge test

: P part one time, one time on the condition of the

connection of every S1∼S4. Total 2 times

- Insulation test

: One time between the connection from P to S1

∼S4 and Core, one time between the connection

from S1∼S4 to P. Total 2 times

- A second voltage test : Output voltage test from every S1∼S4, each one time.

- Power supply : AC 110 V or 220 V, 50 ~ 60 ㎐

- Power supply to test trans : AC 110 V ~ 480 V (variable)

- This Transformer Test System has two test lines(A, B) in order to shorten the loading / unloading time during test.

- Price : (Included Jig)

|

Generator Test System

|

- Generator Test System (grade a 15 ㎾, 30 ㎾)

- Model : KT-GT15K-φ3

- This equipment is test for generator test system of single-phase, 3 - phase output voltage AC 220 V or 380 V 15 kW(20 HP).

As below Figure, the general makeup of motor for driving to generator test system and dummy loader (resistor box), measurement test system.

And a loaded until 1 kW ~ 15 kW or 1 kW ~ 30 kW(grade a 30 ㎾) setting by unit 1 kW, also Good / Bad judgement can be compared with already set up to output voltage, current, power factor, frequency of Generator Test System.

- Characteristic

- Test object

- Output voltage

- Output current

- Output (W)

- Phase angle (power fact)

- Output frequency

- Generator Test System efficiency (calculate according to characteristic of driving motor)

- Variable output (until max. output setting by unit 1 ㎾)

- Capacity : 15 ㎾ ~ 30 ㎾ (20 ~ 40 HP)

- Output voltage : AC 220 V ~ 380 V, single phase,

3 - phase

- Test method : Change of load capacity (1 ㎾ ~ 15 ㎾ or 1 ㎾ ~ 30 ㎾ setting by unit 1 ㎾)

- Price : (15 ㎾)

|

Make-up & Explanation about Generator Test System

- Generator Test System for test

- Driving motor(high efficiency), 20 or 40 HP

- Dummy Loader(resistive box) (15 ㎾ or 30 ㎾)

- Test System (single phase, 3 - phase, change of resistive load)

- The Generator Test System for test is put on the test table(base) and mechanical connect with coupler to driving motor(B).

- Three output line(R, S, T / an example of 3 - phase in figure) of Generator Test System for test (A) connect to three input line of Dummy Loader(resistive box) (C).

- Test equipment(D) is supplied with output voltage and current signal of Generator Test System to Dummy Loader(resistive box) (C) and display a voltage, current, power capacity, output frequency, power fact and control the load.

※ This equipment is manufactured all together to driving gear(driving motor for Generator Test System, coupler,

test table) in KAST but Generator Test System supply company can manufacture driving gear part.